PATENTED PRECIOUS CENTER OF GRAVITY MEASUREMENT ALGORITHM

The necessary patent applications have been made to obtain the intellectual property rights of the algorithms and methods developed by our company in order to increase the precision of the center of gravity measurement and to correct the slope errors, one of the most important sources of error. Thanks to these algorithms and methods, the sensitivity of strain gauge based force-gauges and load cells can be increased, and the errors caused by the deformations of these sensors are minimized during the center of mass calculation phase. This method has provided our products with a worldwide technical advantage over equivalent products.

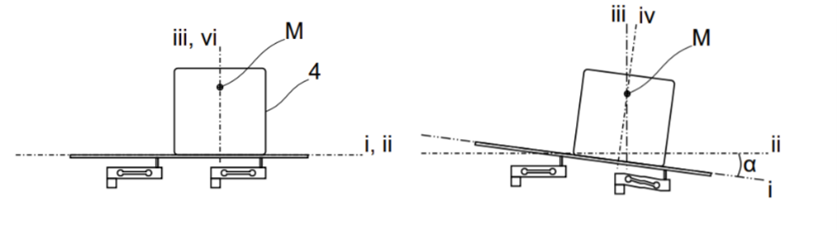

SPECIAL DEGREE OF FREEDOM JOINTS AND MECHANISMS

Mechanical parts required for center of mass and moment of inertia measurement are manufactured with special degrees of freedom. It is not possible for a center of mass measurement system to work precisely without these degrees of freedom calculated based on our technical experience in line with the analysis to be carried out with the principles of axis-guiding and side-load alleviation mechanism. Thanks to these mechanisms, which are produced with high precision with the manufacturing and prototyping capabilities of our company, the mathematical equations used in the center of gravity and moment of inertia calculations can be valid.

MEASUREMENT TABLE DESIGNS THAT MINIMIZE POSITIONING ERROR

In order to measure the center of gravity and moment of inertia of a sample, that sample must be placed in the measuring device as precisely as possible, because this positioning error is directly added to the measurement error, sometimes creating the largest part of the total error. For this reason, our company applies design features such as low tolerance pin holes and machined screw holes to minimize the aforementioned errors in the table and connection parts where the center of mass and moment of inertia measurement devices are connected with the sample. In the photo below, you can see the connection. table of one of our devices.

SPECIALLY DEVELOPED ELECTRONIC EQUIPMENT FOR THE MEASUREMENT OF MASS CHARACTERISTICS

Special electronic cards have been developed by our company in order to control the system components used to measure center of gravity precisely, to receive data from the sensors, to process the received data and to transmit the data to the computer user interface by making the necessary calculations.

Since one of the most important factors that ensure measurement precision is the sensitivity of the data received from various sensors, these electronic cards, which are hardware filtered of electrical and electromagnetic effects, are also used in our systems as a main board in which all components are integrated. Our electronic cards, including the required microprocessors and microcontrollers, are designed to be resistant to environmental conditions and reliable. Thanks to these cards, the data provided by the sensors required for center of gravity and moment of inertia measurements can be obtained and processed precisely.

Thanks to the embedded software in these hardware, data transfer and processing can be performed with high sampling rates and high-resolution analog-digital converters. Thanks to the ability to process the received data by applying special filter algorithms with heavy processing load with ARM based floating point processor architecture, it is possible to perform high accuracy measurements and tests.

HEURISTIC CALIBRATION ALGORITHMS

Karakamlar Inc. has developed heuristic calibration algorithms in order to further increase the precision of the mass properties measurement systems it produces. Thanks to these algorithms, sensor position information is not used when performing system calibration, thus minimizing the effects of manufacturing tolerances and assembly errors on measurement uncertainty of the system.

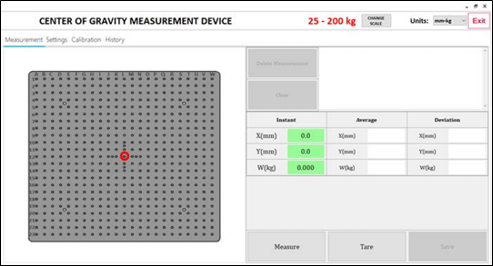

USER FRIENDLY INTERFACE SOFTWARE

Our computer interface software, which is used by hundreds of engineers and technicians from many countries, has been continuously improved over the years thanks to the feedback and comments from these users. Our user-friendly interface software, which is appreciated by our customers at home and abroad, is one of the reasons for choosing our test and measurement systems.

HIGH FREQUENCY OPTICAL SENSORS AND CALCULATION ALGORITHIMS FOR MOMENT OF INERTIA MEASUREMENT

High frequency optical sensors are developed and produced by our company for accurate moment of inertia measurements. With detection capacity lower than 1 ms, our systems can reach 0.001 kg.m2 resolution. In addition, anti-friction mechanical parts and special software algorithms that calculate damping effects increase the measurement results. Also with single measurement system include both Center of gravity and Moment of inertia, the center of gravity offsets can be calculated and correction calculations are added through our user interface easily.